Most of the physical quantities around us are continuous. By continuous we mean that the quantity can take any value between two extreme. For example the atmospheric temperature can take any value (within certain range). If an electrical quantity is made to vary directly in proportion to this value (temperature etc) then what we have is Analogue signal. Now we have we have brought a physical quantity into electrical domain. The electrical quantity in most case is voltage.To bring this quantity into digital domain we have to convert this into digital form. For this a ADC or analog to digital converter is needed. Most modern MCU including AVRs has an ADC on chip. An ADC converts an input voltage into a number. An ADC has a resolution. A 10 Bit ADC has a range of 0-1023. (2^10=1024) The ADC also has a Reference voltage(ARef). When input voltage is GND the output is 0 and when input voltage is equal to ARef the output is 1023. So the input range is 0-ARef and digital output is 0-1023.

|

Fig: ADC Theory |

Inbuilt ADC of AVR

Now you know the basics of ADC let us see how we can use the inbuilt ADC of AVR MCU. The ADC is multiplexed with PORTA that means the ADC channels are shared with PORTA. The ADC can be operated in single conversion and free running more. In single conversion mode the ADC does the conversion and then stop. While in free it is continuously converting. It does a conversion and then start next conversion immediately after that.

ADC Prescaler.

The ADC needs a clock pulse to do its conversion. This clock generated by system clock by dividing it to get smaller frequency. The ADC requires a frequency between 50KHz to 200KHz. At higher frequency the conversion is fast while a lower frequency the conversion is more accurate. As the system frequency can be set to any value by the user (using internal or externals oscillators)( In xBoard™ a 16MHz crystal is used). So the Prescaler is provided to produces acceptable frequency for ADC from any system clock frequency. System clock can be divided by 2,4,16,32,64,128 by setting the Prescaler.

ADC Channels

The ADC in ATmega32 has 8 channels that means you can take samples from eight different terminal. You can connect up to 8 different sensors and get their values separately.

ADC Registers.

As you know the registers related to any particular peripheral module(like ADC, Timer, USART etc.) provides the communication link between the CPU and that peripheral. You configure the ADC according to need using these registers and you also get the conversion result also using appropriate registers. The ADC has only four registers.

- ADC Multiplexer Selection Register – ADMUX : For selecting the reference voltage and the input channel.

- ADC Control and Status Register A – ADCSRA : As the name says it has the status of ADC and is also use for controlling it.

- The ADC Data Register – ADCL and ADCH : The final result of conversion is here.

(Please Read the Tutorial "Internal Peripherals of AVR" before using ADC of AVRs.)

Using the ADC.

In this sample we will setup and use the ADC in single conversion mode. We will connect a LDR( light dependent resistor) which is a light sensor to input. The result will be shown in LCD.

Initialization.

We have to configure the ADC by setting up ADMUX and ADCSRA registers. The ADMUX has following bits.

ADMUX Register.

REFS1 REFS0 selects the reference voltage. See table below –

| REFS1 | REFS0 | Voltage Reference Selection |

| 0 | 0 | ARef internal Vref Turned off |

| 0 | 1 | AVCC |

| 1 | 0 | Reserved |

| 1 | 1 | Internal 2.56 Voltage Reference |

We will go for 2nd option, i.e. Our reference voltage will be Vcc(5v). So we set

ADMUX=(1<<REFS0);

The ADCSRA Register.

- ADEN – Set this to 1 to enable ADC

- ADSC – We need to set this to one whenever we need adc to do a conversion.

- ADIF – This is the interrupt bit this is set to 1 by the hardware when conversion is complete. So we can wait till conversion is complete by polling this bit like//Wait for conversion to completewhile(!(ADCSRA & (1<<ADIF)));The loop does nothing while ADIF is set to 0, it exits as soon as ADIF is set to one, i.e. conversion is complete.

- ADPS2-ADPS0 – These selects the Prescaler for ADC. As I said the ADC frequency must be between 50KHz to 200KHz.

|

We need to select division factor so as to get a acceptable frequency from our 16Mhz clock. We select division factor as 128.So ADC clock frequency = 16000000/128 = 125000 = 125KHz (which is in range of 50KHz to 200KHz). So we set ADCSRA as

ADCSRA=(1<<ADEN)|(1<<ADPS2)|(ADPS1)|(ADPS0); //Enable ADC with Prescalar=Fcpu/128 Reading an analog value.

Now every thing is set up. We now write a routine that will ReadADC.

int16_t ReadADC(uint8_t ch)

u{

//Select ADC Channel ch must be 0-7

ch=ch&0b00000111;

ADMUX|=ch;

//Start Single conversion

ADCSRA|=(1<<ADSC);

//Wait for conversion to complete

while(!(ADCSRA & (1<<ADIF)));

//Clear ADIF by writing one to it

ADCSRA|=(1<<ADIF);

return(ADC);

}

We can call this function from any where from our code and simply need to pass 0-7 as for which channel we need to read.

Sample Code.

The following is complete code to Read Channel 0 and display its value on LCD.

#include <avr/io.h>

#include "lcd.h"

void InitADC(){

MUX=(1<<REFS0); // For Aref=AVcc;A

D

DCSRA=(1<<ADEN)|(1<<ADPS2)|(1<<ADPS1)|(1<<ADPS0); //Rrescalar div factor =128

A

}

nt16_t ReadADC(uint8_t ch)

{u

i

//Select ADC Channel ch must be 0-7

ch=ch&0b00000111;

ADMUX|=ch;

//Start Single conversion

ADCSRA|=(1<<ADSC);

//Wait for conversion to complete

while(!(ADCSRA & (1<<ADIF)));

//Clear ADIF by writing one to it

//Note you may be wondering why we have write one to clear it

//This is standard way of clearing bits in io as said in datasheets.

//The code writes '1' but it result in setting bit to '0' !!!

ADCSRA|=(1<<ADIF);

return(ADC);

}

void Wait(){

uint8_t i;

for(i=0;i<20;i++) _delay_loop_2(0);}

void main(){

uint16_t adc_result;

//Initialize LCD LCDInit(LS_BLINK|LS_ULINE);LCDClear();

//Initialize ADC

InitADC();

//Put some intro text into LCD

LCDWriteString("ADC Test");

LCDWriteStringXY(0,1,"ADC=");

while(1)

{

adc_result=ReadADC(0); // Read Analog value from channel-0 LCDWriteIntXY(4,1,adc_result,4); //Print the value in 4th column second line Wait(); }

}

Hardware

|

Fig: LDR Connected to ADC of AVR |

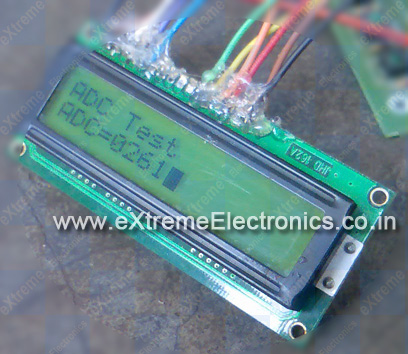

You have to connect a LDR (light dependant resistor) as shown above. After burning the code on chip use a light source to throw some light on LDR, the ADC will show a value between 0-1024 depending on light. For dark the value should be close to 0 while for bright condition the value will become close to 1000.

|

Fig: Screenshot of ADC Test App. |

Note:

- I used the EcxBoard for testing the application but you can use your own development board.See Home Made AVR Devboard.

- You can also get a low cost ATmega8 based board and "USB AVR Programmer" for quick start.

- For LCD Interfacing See- "LCD Interfacing Tutorial"

- Please Read the Tutorial "Internal Peripherals of AVR" before using ADC of AVRs.

More AVR ADC Applications

- Interfacing Temperature Sensor – LM35

- Interfacing MMA7260 Triple Axis Accelerometer with ATmega32

- AVR Graphic LCD and Accelerometer Demo

- Visualize ADC data on PC Screen using USART – AVR Project

© 2011 Electroclub |

03:20

03:20

technoclub

technoclub

0 comments:

Post a Comment